Total protection,

maximum breathability

Membranes

Akkotex is able to provide a wide choice of membranes

selected for every type of need and coupling.

From the ultra-thin 5 microns in polyester up to a thickness

of over 30 microns for the microporous PTFE versions.

All fabrics coupled with Akkotex polyester membranes are labeled

with the X-Tex® brand which guarantees their waterproofness and

high level of breathability and avoids transmigration of colors during printing.

Polyester Membrane

X-Tex® Polyester Membranes are waterproof, breathable, high temperature resistant and with good elasticity. They can have different thicknesses based on the type, resistance and elasticity that you want to obtain from the final fabric. They are osmotic breathable and are mainly used in the production of technical fabrics for sublimation printing, or for processes and applications where high temperatures develop.

Polyurethane Membrane

This kind of membrane is both waterproof and breathable and with excellent elasticity, in fact, they are used to produce sport, fashion, and technical fabrics. However, the high level of elasticity makes them less suitable for subsequent processing on materials (such as sublimation printing).

PTFE Membrane

PTFE membranes are with “direct perspiration” thanks to the structure with billions of micro holes that let the steam expel directly towards the outside. At the same time, they are waterproof with a resistance of 10 meters of water per square centimetre. They are non-elastic membranes, used extensively in the technical footwear and outdoor clothing fields.

Micro-porous Polyurethane Membrane

These membranes allow direct breathability thanks to their light and micro-porous structure. They allow the fabrics to acquire waterproofness, breathability, wind protection and time resistance characteristics. They are mainly used in the Outdoor and Technical Sectors.

Graphene Membrane

Graphene membranes have a high elasticity (as they are produced on a polyurethane basis), high waterproofness and breathability, they offer also particular advantages to the fabrics with which they are coupled. Graphene is highly thermally conductive, thermoregulating and bacteriostatic and makes the fabric suitable for protection from wind and rain. With fabrics coupled with graphene membranes it’s possible to create very technical and cutting-edge garments both in the sports but also technical and medical sectors.

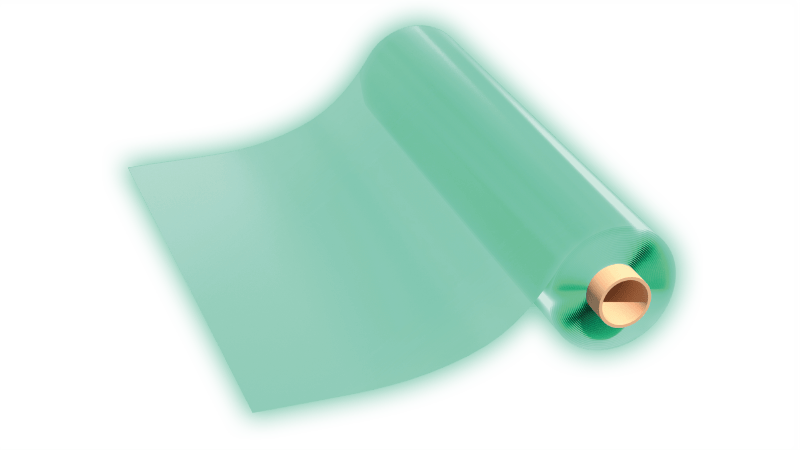

Luminescent Membrane

Photo-luminescent membranes allow the realization of fabrics that absorb UV Rays both natural and artificial.

The light is released when the material is in a light-free location. They are used to produce technical garments or to create innovative products for night use.

Available both in classic yellow-green version and in blue-ocean color.

Printed/Personalized Membrane

The printable membranes are polyurethane-based, they maintain high values of elasticity, breathability and waterproofness and they are customizable both in the basic color and in the graphic design, which is created with direct printing on the membrane. They are used for making 2-layer technical fabrics, where the customer wants to maintain a lightweight, high protection, with a design or a characteristic color inside the fabric.

Bioceramic Membrane

Bioceramic membranes maintain all the properties of other membranes in terms of breathability and protection and emit FIR rays with all their beneficial characteristics. They are used for laminating technical fabrics in the medical, sports, competitive, and footwear sectors.

Outdoor membrane

The outdoor membranes are designed to create 2-layer technical fabrics, with the characteristic of having the insulating part of the fabric inside and outside the protective part from wind and rain. Used a lot in both fashion and technical sectors, they can be of various colors, including Pantone ones.